Industry Standards Met by Optical Fibre Diameter Analyser Systems

Industry Standards Met by Optical Fibre Diameter Analyser Systems

Blog Article

Maximize Your Fiber Optic Performance: Comprehending Optical Fibre Diameter Analyser Modern Technology

The performance of fiber optic systems is seriously influenced by the accuracy of their diameter, an element usually forgot in the pursuit of optimum signal stability. Understanding the modern technology behind optical fiber size analysers reveals the intricate equilibrium in between dimension accuracy and production quality.

Importance of Optical Fiber Size

The size of optical fibre plays a critical function in determining the efficiency and efficiency of interaction systems. It influences several vital parameters, including the mode of light proliferation, attenuation, and data transfer ability. Larger sizes normally permit numerous light modes, helping with greater data transmission prices. On the other hand, smaller sizes often tend to support fewer modes, which can enhance signal clearness and lower crosstalk.

Moreover, comprehending the size's effects can result in set you back savings by lowering the requirement for signal amplification and repeaters in extensive networks (optical fibre diameter analyser). Finally, the importance of optical fiber diameter can not be overstated, as it straight influences the general performance and reliability of modern communication systems

Exactly How Diameter Affects Signal Quality

Signal quality in optical fibre systems hinges considerably on the size of the fiber. A smaller diameter can lead to higher depletion prices, resulting in signal loss as light journeys through the fibre.

Conversely, bigger sizes typically allow for enhanced light capture and decreased modal dispersion, enhancing signal clearness. In multimode fibers, a bigger core size can sustain several light settings, but it may also introduce intermodal diffusion, which can deteriorate signal high quality. As a result, choosing the optimum fibre size is critical for attaining the desired efficiency in certain applications.

Furthermore, the interaction in between the fibre diameter and the wavelength of the light made use of plays a critical role in establishing the reliable transmission range and total signal honesty. Therefore, understanding just how fibre diameter influences signal top quality is vital for network designers and designers aiming to enhance optical fibre systems for trustworthy, high-speed data transmission.

Overview of Diameter Analyser Innovation

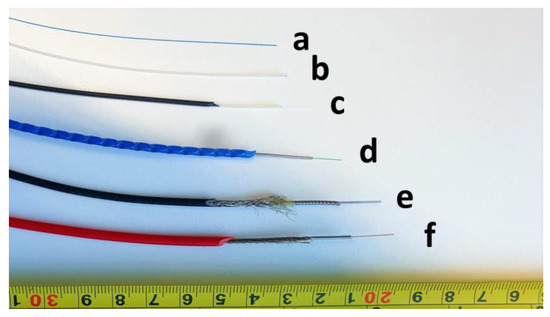

In numerous optical fiber production procedures, exact measurement of fiber size is vital for guaranteeing consistent performance and top quality (optical fibre diameter analyser). Diameter analysers are innovative tools designed to examine the physical dimensions of optical fibres with high accuracy. They employ advanced optical and laser technologies to gauge the diameter, ovality, and concentricity of the fiber, therefore giving crucial information for high quality control

These analysers can operate in-line during the manufacturing procedure or as part of off-line screening protocols. In-line systems allow real-time monitoring, permitting producers to readjust criteria quickly, thereby maintaining optimum production problems. Off-line analysers, on the other hand, give extensive evaluations of batches, making certain that any deviations from defined tolerances are recognized and addressed.

Size analysers considerably add to the decrease of problems in optical fibres, boosting total item integrity. By consistently measuring essential criteria, these innovations assist in compliance with sector standards and specs. As the need for high-performance optical fibers continues to rise, the duty of size analysers comes to be significantly essential in accomplishing the desired top quality and performance standards in fiber optic systems.

Secret Attributes of Fiber Size Analysers

Although various models of fibre size analysers exist, they generally share several essential attributes that boost their functionality and reliability. One of the most substantial attributes is high-resolution dimension capacities, which ensure precise size readings, important for preserving top quality control in fiber manufacturing. Additionally, many analysers incorporate innovative optical sensing units made to detect minute variations in fiber size, thus giving vital information for process optimization.

Another vital function is real-time tracking, permitting operators to receive prompt responses on fiber diameter throughout the production procedure (optical fibre diameter analyser). This capacity assists in quick adjustments and reduces image source the likelihood of defects. Numerous analysers also come equipped with user-friendly interfaces, allowing drivers to easily browse with data and setups outputs

Moreover, robust data storage and analysis capabilities are essential for tracking historical performance fads and making sure conformity with market requirements. Some versions even offer connectivity alternatives for integration into existing manufacturing control systems, enhancing overall functional effectiveness. Small and mobile styles enable for flexible deployment within manufacturing environments, guaranteeing that quality guarantee processes are smooth and efficient. These features jointly contribute to the effectiveness of fiber diameter analysers in maximizing fiber optic efficiency.

Finest Practices for Fiber Optimization

First, normal calibration of optical fibre diameter analysers is essential. This makes certain exact dimensions and minimizes potential disparities that could influence performance. Next off, preserving a clean workplace is essential; dirt and pollutants can cause indicate degradation.

Furthermore, it is very important to pick fibres that fulfill certain application requirements. This great site involves reviewing factors such as depletion, bandwidth, and ecological conditions. Proper installation strategies must additionally be stuck to, including avoiding sharp bends and excessive stress, which can compromise fiber integrity.

Furthermore, utilizing sophisticated tracking systems can promote real-time performance evaluations, enabling punctual identification of concerns. Routine screening and upkeep must be performed to ensure that fibres stay within ideal functional criteria.

Finally, training employees on the latest fibre optimization technologies and techniques will boost their capacity to carry out efficient strategies. By adhering to these finest techniques, organizations can dramatically improve the performance and life expectancy of their optical fiber systems, ensuring reliable interaction and data transfer.

Verdict

In verdict, the combination of optical fibre size analyser innovation is vital for taking full advantage of fiber optic efficiency. By making certain precise measurements of fiber dimensions, these analysers dramatically improve signal top quality and reduce losses during information transmission. Routine calibration and maintenance of the analysers are important to maintain optimal efficiency and compliance with industry criteria. Ultimately, the application of this technology assists in boosted data transmission prices and strengthens signal stability, adding to the total performance of fibre optic systems.

Signal quality in optical fibre systems pivots significantly on the size of the fibre.In many optical fiber manufacturing processes, exact measurement of fibre diameter is necessary for guaranteeing regular performance and quality. As the demand for high-performance optical fibres continues to rise, the go to this web-site role of size analysers comes to be increasingly important in achieving the preferred quality and performance criteria in fiber optic systems.

These attributes collectively add to the effectiveness of fibre diameter analysers in optimizing fiber optic efficiency.

In final thought, the integration of optical fiber diameter analyser modern technology is essential for optimizing fibre optic performance.

Report this page